The Paris Olympics are coming soon, and the sports equipment favored by athletes is getting a lot of attention. Although not as well-known as sports brands like Nike, Adidas, and Asics, Hoka One One has been gaining popularity in recent years. As a professional sports brand loved by athletes, where does Hoka produce such high-quality products? This article will give you a detailed look.

Hoka Origin

Who Makes Hoka Shoes?

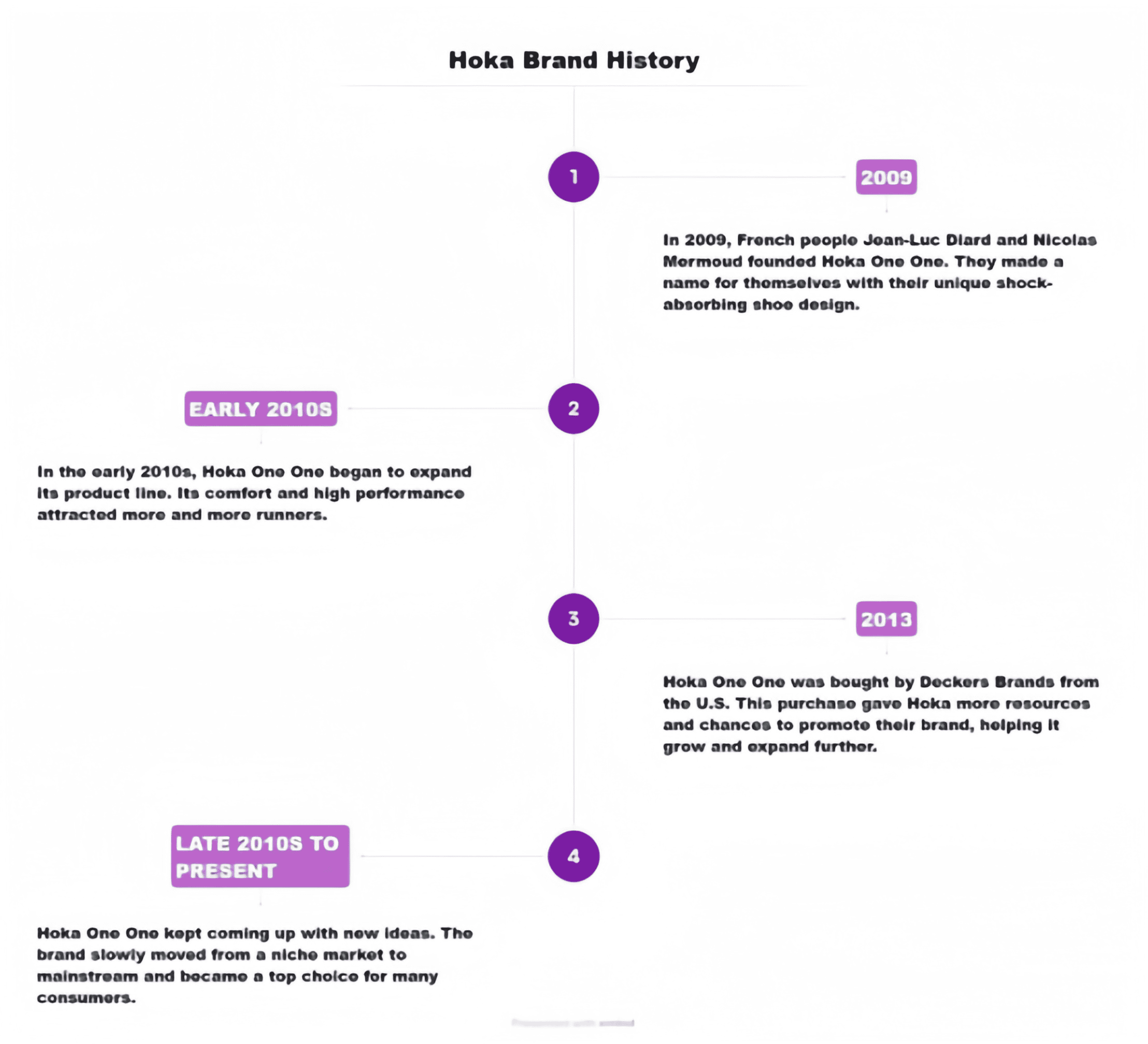

Have you heard of the Hoka One One company? From the name, you can tell that Hoka shoes are designed and made by this company. In 2009, Jean-Luc Diard and Nicolas Mermoud started Hoka One One. They first made shoes for trail running, but now they make all kinds of sports shoes. Their shoes are popular with many sports fans because they are both stylish and useful.

Hoka Brand History

Are Hoka Shoes Made in China?

Hoka One One shoes are mainly made in China. This is because China has low production costs, good infrastructure, and a complete supply chain. In China, 50%-60% of Hoka shoes are made. But Hoka shoes are also made in other Asian countries like Vietnam and Indonesia. If you want to know where a pair of Hoka shoes was made, it’s easiest to check the label on the shoe.

Which Factories in China Might be Suppliers for Hoka?

1.Yue Yuen Industrial Holdings Limited

Number of Employees

About 350,000 employees.

Headquarters Address

11/F, Harbour Centre, 223-231 Wai Yip Street, Kwun Tong, Kowloon, Hong Kong.

Factory Location

Guangdong Province: Dongguan City, Huizhou City

Fujian Province: Jinjiang City, Quanzhou City

Good at Direction

- Production of high-performance sports shoes.

- Intelligent production and automated production.

- Environmental protection and sustainable production.

Production Certification

- ISO 9001: Quality Management System Certification

- ISO 14001: Environmental Management System Certification

- OHSAS 18001: Occupational Health and Safety Management System Certification

Features

- Good product quality

- Good innovative design

Delivery Time

Delivery within 30-90 days after order confirmation.

2.Pou Chen Corporation(Subsidiary of Yue Yuen Industrial Holdings Limited)

Number of Employees

About 450,000 employees.

Headquarters Address

No. 22, Datong Road, Yuanlin City, Changhua County, Taiwan.

Factory Address

Guangdong Province: Dongguan City, Huizhou City

Fujian Province: Jinjiang City, Quanzhou City

Jiangsu Province: Yangzhou City

Good at Direction

- Production of high-performance sports shoes.

- Intelligent production and automated production.

- Environmentally friendly and sustainable production.

Production Certification

- ISO 9001: Quality Management System Certification

- ISO 14001: Environmental Management System Certification

- OHSAS 18001 / ISO 45001: Occupational Health and Safety Management System Certification

- SA 8000: Social Responsibility Standard Certification

Features

- Use environmentally friendly materials

- Good product quality

- Creative product design

Delivery Time

Delivery within 30-90 days after order confirmation.

3.Feng Tay Enterprises Co., Ltd.

Number of Employees

More than 60,000 employees.

Headquarters Address

No. 10, Gongye 15th Road, Industrial Park, Taichung City, Taiwan.

Factory Address

Guangdong Province: Dongguan City

Fujian Province: Jinjiang City

Good at Direction

- Production of high-performance sports shoes.

- Innovative footwear design.

- Environmentally friendly production strategies.

Production Certification

- ISO 9001: Quality Management System Certification

- ISO 14001: Environmental Management System Certification

- OHSAS 18001: Occupational Health and Safety Management System Certification

- SA 8000: Social Responsibility Standard Certification

Features

- Focus on comfort and functionality

- Innovative design and high quality

Delivery Time

Delivery within 45-90 days after order confirmation.

4.Kuan Chang Enterprises Co., Ltd.

Number of Employees

Approximately 10,000 employees.

Headquarters Address

Taichung City, Taiwan.

Factory Address

Guangdong Province: Dongguan City

Fujian Province: Quanzhou City

Good at Direction

- High-performance sports shoe manufacturing.

- Customized and innovative design.

- Use of environmentally friendly materials.

Production Certification

- ISO 9001: Quality Management System Certification

- ISO 14001: Environmental Management System Certification

- OHSAS 18001: Occupational Health and Safety Management System Certification

- SA 8000: Social Responsibility Standard Certification

Features

- High product quality

- Creative product design

- Comfortable and functional

Delivery Time

Delivery within 45-90 days after order confirmation.

5. Stella International Holdings Limited

Number of Employees

Approximately 20,000 employees.

Headquarters Address

22/F, Pak Lee Building, 333 Nathan Road, Kowloon, Hong Kong.

Factory Address

Guangdong Province: Dongguan City

Fujian Province: Jinjiang City

Good at Direction

- High-end sports and fashion footwear manufacturing.

- Full supply chain management.

- Environmentally friendly and sustainable production.

Production Certification

- ISO 9001: Quality Management System Certification

- ISO 14001: Environmental Management System Certification

- OHSAS 18001: Occupational Health and Safety Management System Certification

- SA 8000: Social Responsibility Standard Certification

Features

- Focus on comfort, functionality and durability

- Good product quality

- Creative product design

Delivery Time

Delivery within 45-90 days after order confirmation.

How Is the Quality of Hoka?

Overall, Hoka One One has top-quality products in the market. Both professional athletes and sports fans give Hoka running shoes good reviews. This shows that Hoka works hard to keep their product quality high, which can be seen in four main ways.

1. Excellent Shock Absorption Performance

Hoka shoes are most famous for their cushioning technology. This is why Hoka shoes sell so well every year. The high quality and special technology make Hoka shoes unique. The thick sole design gives great comfort and shock absorption, which other brands can’t match.

2. Lightweight Design

Usually, shoes with thick soles are heavy and not good for sports. They can be a burden for athletes. But Hoka shoes are different. Hoka carefully chooses materials and uses special designs. So, even though the soles are thick, the shoes are very light. They feel comfortable and are good for long-term wear and long runs.

3. Stable Support

Hoka shoes have a clear target group: athletes. To meet their needs and protect their feet and knees, many Hoka shoes offer good support and stability. A good product meets the needs of its target group.

4. Good Durability

Besides these special features, Hoka shoes are also very durable. They can be worn for a long time, which makes them very attractive to customers.

How Does Hoka Quiz the Quality of Its Products?

Material Selection

Hoka has invested a lot in choosing materials to develop new, high-quality, high-performance materials. They also perform many laboratory tests on the quality and performance of materials, followed by long-term use tests to ensure the durability of the materials. The materials used in making a product are the foundation of the product. These steps lay a solid foundation for Hoka’s high quality.

Model Making

Before launching a shoe, Hoka first makes a model. Then, they perform many quality tests on this model, such as simulating the shoe’s performance on a computer and doing laboratory and field tests. These tests confirm that the product’s quality and performance meet the standards.

Lab Testing

To ensure product quality, Hoka often performs laboratory tests. They mainly do tests on material performance (testing the cushioning, wear resistance, and breathability of materials), sole performance (testing the grip of the soles and their durability after bending), and stability tests (testing the support and slip resistance of the shoes). This is to make sure that every product meets Hoka’s high standards.

Testing on the Spot

Besides laboratory tests, Hoka also does field tests to make sure their shoes are comfortable and of good quality in everyday use. They not only have regular customers try on the shoes, but also recruit professional athletes to wear them. They test the quality of the shoes, collect feedback, and record data to improve their products.

Customer Feedback

Hoka One One really cares about customer feedback and uses it as a key way to improve product quality. Hoka collects user feedback through surveys, social media, third-party shopping platforms, and customer service records. They analyze the issues from customer feedback to improve their products.

Production Monitoring

To control product quality, Hoka sets up multiple quality control points on the production line and trains employees to be aware of quality control. They check the quality at every step. Besides, Hoka uses automated production in many processes to reduce human errors, which increases the efficiency and consistency of the products. After production, they also do sample checks and performance tests on the products.

FAQ

Is Hoka an American Company?

Even though it was said earlier that Hoka One One was started by two French people, in 2013, the American company Deckers Outdoor Corporation bought Hoka. Now, Hoka is part of Deckers, making it an American company. Its headquarters are currently in Goleta, California, USA.

Where do Hoka Products Manufactured in China Ship from?

Since Hoka products made in China have different places of production and destinations, there are many shipping options available. You can ship directly from the factory, through distribution centers, work with third-party logistics, or use e-commerce platform delivery services. You can choose the best shipping method based on your needs to ensure your goods are transported quickly and efficiently to their destination.

How to Cooperate with Hoka’s Chinese OEM Factory?

First, you need to pick a suitable Hoka factory and contact them to ask about cooperation. If possible, it’s best to visit the factory in person to check if the production conditions and processes are standard.

Before placing an order, I strongly suggest you get a sample first. Check the sample’s quality, specifications, color, and design to see if they meet your requirements before ordering large-scale production to avoid wasting time and money. Also, remember to understand the contract terms in detail and negotiate to get a fair price and service.

After the products are made, you should learn about the laws and plan your logistics and customs clearance to ensure your products arrive on time. Once the products arrive, remember to inspect them and give feedback to the supplier to avoid repeating issues in future collaborations.

Conclusion

Hoka has maintained its original intention and kept its product quality high over the years, which is not easy. Its quality control model and choice of production location are worth your reference. If you want to work with a Chinese Hoka manufacturer to produce high-quality products for your brand, no matter what difficulties you face, feel free to consult us at SourcingWise. We will bring our team to provide the best and most professional service suited to your needs.